When it comes to measuring fluid movement, accuracy is everything. Whether you’re tracking water, gas, oil, or steam, choosing the right flow meter can save time, money, and headaches. But with so many types of flow meters on the market, how do you know which one fits your needs?

In this article, we’ll break down the main types of flow meters, explain how each one works, and help you identify the best option for your specific application. By the end, you’ll be equipped with the knowledge to make a smart, confident decision—no guesswork required.

What Is a Flow Meter?

A flow meter is a device used to measure the volume, speed, or mass of a fluid (liquid or gas) as it moves through a pipe or channel. Industries rely on them for everything from water treatment and oil refining to energy production and HVAC systems.

The right flow meter isn’t just about cost—it’s about performance, reliability, and long-term maintenance. And as someone who runs a company dedicated to delivering accurate, reliable, and maintenance-free energy measurement solutions, I can tell you: it pays to get this choice right from the start.

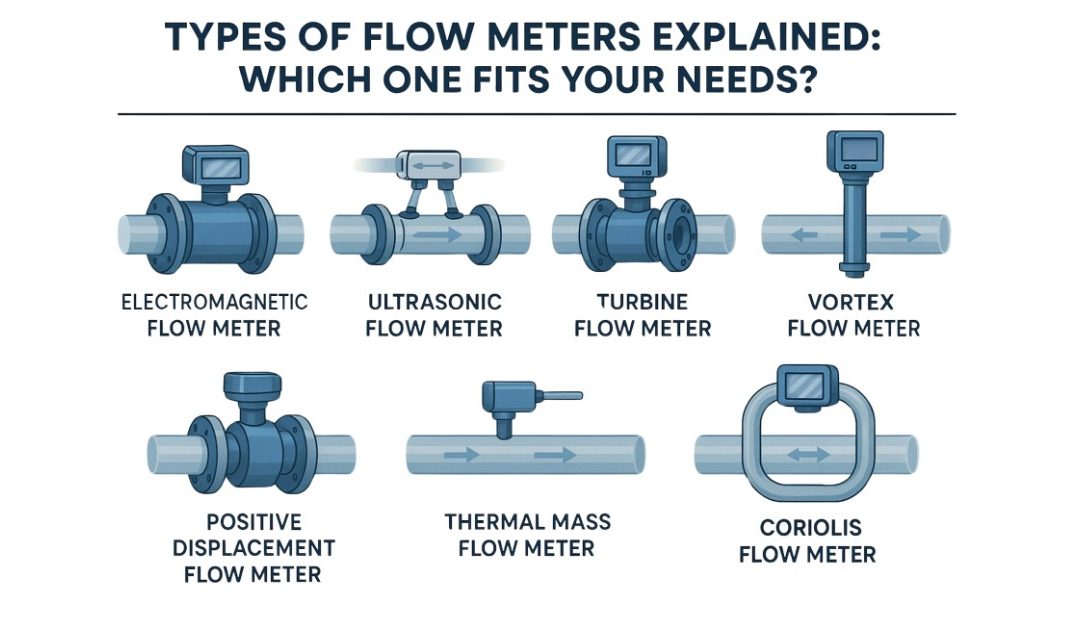

The Main Types of Flow Meters

Let’s get straight to it. Here are the most commonly used types of flow meters, explained in simple, no-nonsense terms.

1. Electromagnetic Flow Meters (Mag Meters)

How They Work:

Mag meters use electromagnetic fields to measure the flow of conductive liquids—like water, sludge, or slurry.

Pros:

✅ No moving parts

✅ Low maintenance

✅ Excellent accuracy for conductive fluids

Cons:

❌ Doesn’t work with non-conductive fluids (like oil or gas)

Best For:

Water treatment plants, mining, and pulp & paper industries.

2. Ultrasonic Flow Meters

How They Work:

These meters send ultrasonic sound waves through the fluid. The flow rate is calculated based on the time it takes for the signal to travel with and against the flow.

Pros:

✅ Non-invasive (can be clamped to the outside of the pipe)

✅ No pressure drop

✅ Works with both liquids and gases

Cons:

❌ Can be less accurate with bubbles, solids, or dirty fluids

Best For:

Clean water, natural gas, and HVAC systems

3. Turbine Flow Meters

How They Work:

Fluid passes through the meter and spins a rotor. The speed of the rotor is proportional to the flow rate.

Pros:

✅ High accuracy in clean, steady flow conditions

✅ Affordable option

Cons:

❌ Mechanical parts wear over time

❌ Not suitable for dirty or viscous fluids

Best For:

Fuel systems, clean water, and chemical dosing

4. Vortex Flow Meters

How They Work:

As fluid flows past a bluff body (a fixed obstruction), it creates swirling vortices. These vortices are counted to measure flow.

Pros:

✅ No moving parts

✅ Handles steam, gas, and liquids

✅ Good all-rounder

Cons:

❌ May struggle with low flow rates

❌ Can be affected by pipe vibrations

Best For:

Steam systems, compressed air, and industrial gases

5. Positive Displacement (PD) Flow Meters

How They Work:

These meters trap small amounts of fluid and count how many times the chamber fills and empties.

Pros:

✅ Extremely accurate

✅ Works well with viscous fluids

Cons:

❌ Slower response time

❌ Higher maintenance

Best For:

Oil and lubricant systems, food and beverage industries

6. Thermal Mass Flow Meters

How They Work:

They measure how much heat a fluid absorbs as it flows past a heated sensor.

Pros:

✅ Great for gas flow

✅ Measures mass flow directly

Cons:

❌ Affected by changes in gas composition

❌ Not ideal for liquids

Best For:

Compressed air, natural gas, and environmental monitoring

7. Coriolis Flow Meters

How They Work:

These meters measure mass flow by detecting changes in vibration caused by fluid motion in a curved tube.

Pros:

✅ Highest accuracy

✅ Measures both mass and density

✅ Works with almost any fluid

Cons:

❌ Expensive

❌ Sensitive to vibration

Best For:

Pharmaceutical, oil & gas, and food processing applications

Choosing the Right Flow Meter

With so many types of flow meters to choose from, you need to ask the right questions:

➡️ What type of fluid are you measuring (liquid, gas, slurry)?

➡️ Is the fluid clean or dirty?

➡️ Do you need high accuracy, or is a general reading enough?

➡️ What are the flow rate and pressure conditions?

➡️ Will you need a maintenance-free solution?

For example, if you’re working with clean water and need something low-maintenance, an ultrasonic flow meter might be perfect. But if you’re measuring fuel in a high-pressure line, a turbine meter could be your best bet. And if accuracy is non-negotiable, nothing beats a Coriolis meter—assuming your budget allows.

Why Maintenance-Free Meters Matter

Downtime kills productivity. That’s why low-maintenance and non-intrusive types of flow meters are gaining traction. Our company specializes in delivering maintenance-free solutions that perform consistently in harsh environments. When you reduce moving parts and eliminate the need for recalibration, you’re not just saving labor—you’re safeguarding uptime.

For more technical guidance and standards, check out the U.S. Department of Energy’s guide on flow measurement to get deeper insights into system efficiency and meter selection.

Final Thoughts

There’s no one-size-fits-all when it comes to flow measurement. Each application has its own demands. But understanding the types of flow meters available—and what they’re best suited for—puts you ahead of the game.

Whether you’re dealing with clean water, steam, corrosive chemicals, or natural gas, there’s a meter designed for your specific challenge. And if you’re looking for a solution that’s not just precise, but also reliable, rugged, and maintenance-free, don’t hesitate to reach out. It’s not just about measuring flow—it’s about improving performance across your entire operation.

Need Help Choosing?

Talk to one of our experts today. We’ll walk you through the selection process based on your unique requirements, helping you avoid common pitfalls and find the perfect fit.

FAQ

What are the different types of flow meters?

There are several main types of flow meters, including electromagnetic, ultrasonic, turbine, vortex, positive displacement, thermal mass, and Coriolis flow meters. Each type is suited to specific fluid types, conditions, and industries.

Which type of flow meter is the most accurate?

Coriolis flow meters are generally considered the most accurate because they measure mass flow directly and handle a wide range of fluids. However, they can be costly and sensitive to vibration.

How do I choose the right flow meter for my application?

To choose the right flow meter, consider the type of fluid (liquid or gas), whether it’s clean or dirty, the required accuracy, flow rate range, and maintenance preferences. Environmental factors and budget also play a role.

What is the difference between mass flow and volumetric flow meters?

Mass flow meters measure the mass of the fluid passing through, while volumetric flow meters measure the volume. Mass flow meters are more accurate in applications where fluid density or temperature changes.

Do all flow meters require regular maintenance?

Not all flow meters require frequent maintenance. Non-intrusive options like ultrasonic and electromagnetic meters have no moving parts and are often considered maintenance-free, making them ideal for long-term, reliable use.

Can a single flow meter work for both liquids and gases?

Some flow meters, like ultrasonic and vortex meters, can handle both liquids and gases. However, it’s essential to check the specifications of the meter to ensure compatibility with your exact media.

What industries use flow meters?

Flow meters are widely used in water treatment, oil and gas, energy production, HVAC, chemical processing, food and beverage, and pharmaceutical industries.

Are there flow meters that don’t require pipe cutting or system shutdown?

Yes. Clamp-on ultrasonic flow meters can be installed externally, meaning there’s no need to cut into the pipe or shut down operations. They’re ideal for retrofits and quick installations.