In today’s energy-conscious world, precise measurement of thermal energy is paramount for optimizing efficiency and reducing costs. Traditional methods often fall short in accuracy and maintenance requirements. Enter the Condensate BTU Meter, specifically the HEATX2, which offers a groundbreaking approach to energy measurement by focusing on condensate rather than steam. This article explores how the HEATX2 sets a new standard in energy metering.

Understanding the Condensate BTU Meter

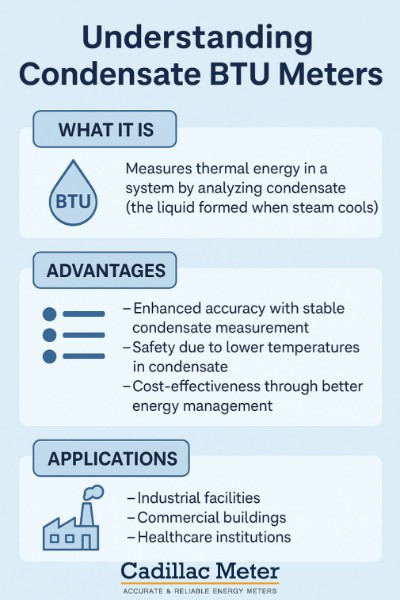

A Condensate BTU Meter measures the thermal energy in a system by analyzing the condensate—the liquid formed when steam cools. Unlike conventional meters that assess steam flow, condensate measurement provides a more stable and accurate representation of energy usage. This method mitigates issues like fluctuating steam densities and high temperatures that can compromise measurement accuracy.

The HEATX2 Advantage

The HEATX2 stands out as a premier Condensate BTU Meter, offering unparalleled accuracy and reliability. Its design addresses common challenges in energy measurement:

-

Enhanced Accuracy: By measuring condensate, the HEATX2 avoids the variability inherent in steam measurements, leading to more precise energy readings.

-

Maintenance-Free Operation: The system’s robust design minimizes wear and tear, reducing the need for frequent maintenance and ensuring long-term reliability.

-

Comprehensive Data Analysis: Equipped with advanced sensors and data processing capabilities, the HEATX2 provides detailed insights into energy consumption patterns.

Why Measure Condensate?

Measuring condensate offers several benefits over traditional steam measurement:

-

Stability: Condensate has consistent properties, making it easier to measure accurately.

-

Safety: Lower temperatures in condensate reduce risks associated with high-temperature steam measurements.

-

Cost-Effectiveness: Accurate measurements lead to better energy management, resulting in cost savings.

As highlighted by industry experts, measuring on the condensate side can provide greater accuracy and safety compared to steam-side measurements.

Applications Across Industries

The HEATX2’s capabilities make it suitable for various sectors:

-

Industrial Facilities: For monitoring energy usage in manufacturing processes.

-

Commercial Buildings: To manage heating systems efficiently and reduce operational costs.

-

Healthcare Institutions: Ensuring precise energy monitoring for critical systems.

Integration and Compatibility

The HEATX2 is designed for seamless integration into existing systems:

-

User-Friendly Interface: Simplifies monitoring and data interpretation.

-

Flexible Connectivity: Compatible with various communication protocols for easy integration with building management systems.

-

Scalability: Suitable for both small-scale applications and large industrial setups.

Environmental Impact

Accurate energy measurement contributes to sustainability:

-

Reduced Energy Waste: Precise monitoring helps identify and eliminate inefficiencies.

-

Lower Carbon Footprint: Efficient energy use translates to reduced greenhouse gas emissions.

-

Compliance: Assists in meeting environmental regulations and standards.

Conclusion

The Condensate BTU Meter, exemplified by the HEATX2, represents a significant advancement in energy measurement technology. By focusing on condensate, it offers enhanced accuracy, reliability, and efficiency. For organizations aiming to optimize energy use and reduce costs, the HEATX2 provides a compelling solution.

For more information on condensate measurement and its benefits, visit this authoritative resource: What Are Condensate Meters? A Complete Guide.

FAQ

❓ What is a Condensate BTU Meter?

A Condensate BTU Meter is a device that measures the amount of thermal energy in a system by analyzing condensate—the liquid formed when steam cools. It provides a more accurate and stable way to track energy usage compared to traditional steam-side measurement.

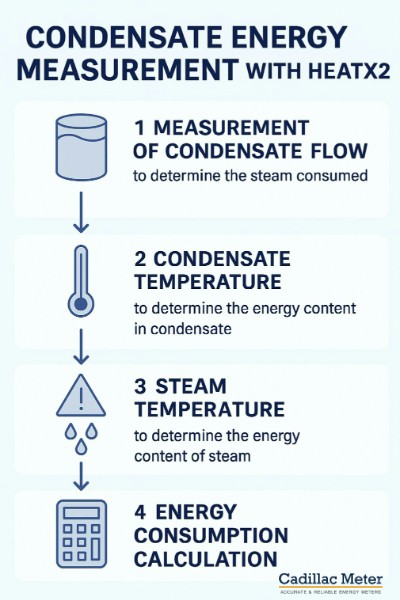

❓ How does the HEATX2 measure energy using condensate?

The HEATX2 uses precision sensors to monitor both the flow rate and temperature of condensate return lines. By calculating the energy removed from the steam, it delivers accurate BTU readings without the variability of steam-side measurements.

❓ Why is measuring condensate better than measuring steam?

Condensate has a consistent temperature and density, making it far easier to measure accurately. Steam can be volatile, with changing pressure and temperature, which makes steam-side readings less reliable and more prone to error.

❓ What are the benefits of using the HEATX2 Condensate BTU Meter?

✅ Greater measurement accuracy

✅ Minimal maintenance requirements

✅ Enhanced safety due to lower operating temperatures

✅ Cost savings through improved energy monitoring

❓ Who should use a Condensate BTU Meter like the HEATX2?

Any facility with a steam system can benefit — including industrial plants, commercial buildings, universities, and healthcare institutions — especially those looking to optimize energy use and reduce costs with accurate data.

❓ Is the HEATX2 compatible with existing systems?

Yes. The HEATX2 is designed for easy integration with most building management systems (BMS) and can be scaled for both small and large applications.