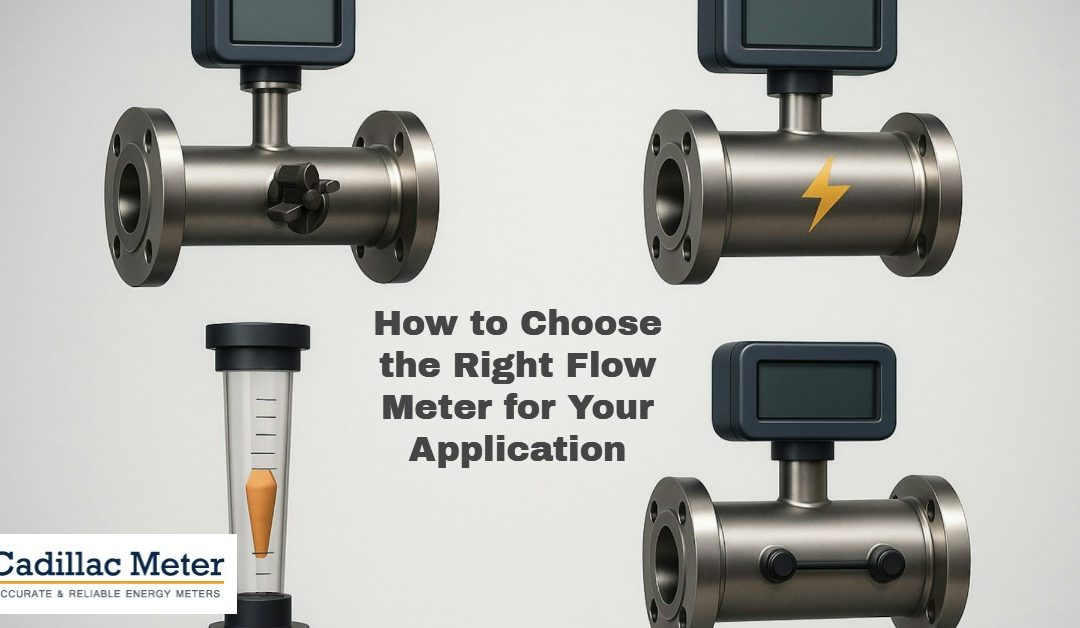

Choosing the right flow meter for your application is critical for ensuring accurate, reliable, and cost-effective fluid measurement. Whether you’re measuring water, gas, steam, or chemical flows, the device you select must align with your system’s specific requirements. In this article, we’ll break down the essential factors to consider and help guide you through how to choose the right flow meter for your needs.

Understanding What a Flow Meter Does

A flow meter is a device used to measure the volume or mass of a fluid moving through a pipe. They are essential in various industries, including water treatment, HVAC, energy, oil and gas, and chemical manufacturing. The accuracy and reliability of your readings depend heavily on the meter type you select.

Why Getting It Right Matters

Making the wrong choice can lead to operational inefficiencies, increased maintenance, safety issues, and unnecessary costs. That’s why understanding how to choose the right flow meter is not just about matching specs but about long-term performance, reliability, and maintenance.

1. Identify the Fluid Type

First and foremost, you need to know what fluid you’re measuring. Is it a liquid or a gas? Is it clean or dirty? Does it contain particulates or bubbles? Viscosity, conductivity, temperature, and pressure all play roles in meter performance.

- Water: Often uses ultrasonic or electromagnetic meters

- Gas: Thermal or differential pressure meters are common

- Steam: Vortex flow meters are frequently used

- Slurries or viscous fluids: Positive displacement or Coriolis meters may be better suited

Understanding your medium will immediately narrow down your options.

2. Define Your Measurement Needs

Ask yourself: Do you need to measure volume flow rate or mass flow rate? Some applications require precision in volume, while others need accuracy in mass regardless of temperature or pressure.

- Volumetric meters include turbine, ultrasonic, and electromagnetic

- Mass flow meters include Coriolis and thermal

You also need to consider the range of flow you want to measure. Make sure the meter performs well across all expected flow conditions.

3. Consider Pipe Size and Installation Constraints

Flow meters come in different sizes and configurations. Your existing pipe diameter, layout, and available space may limit your choices.

For example:

- Clamp-on ultrasonic meters are ideal when you can’t cut into pipes

- Inline meters may require straight runs before and after the meter to ensure accuracy

- Insertion meters can be installed without shutting down operations

4. Determine Accuracy Requirements

Not all applications need ultra-high accuracy. For example:

- Billing or custody transfer applications demand ±0.1% or better

- Process control may tolerate ±1% to ±2%

- General monitoring may allow up to ±5%

Always check the manufacturer’s specifications and compare accuracy under real-world conditions, not just lab results.

5. Evaluate the Environment

Environmental conditions such as temperature, humidity, and exposure to chemicals or vibration can impact your meter’s lifespan and performance.

Choose a device rated for your specific environment. For instance:

- If your process involves high temperatures, ensure thermal tolerance

- If outdoors, weatherproof enclosures may be needed

- In explosive areas, intrinsically safe devices are required

6. Review Maintenance and Calibration Needs

Downtime is expensive. That’s why it’s crucial to consider how often a meter will need calibration or maintenance.

- Electromagnetic meters often require little maintenance

- Mechanical meters (like turbine or positive displacement) may wear over time

- Some meters are self-diagnosing or come with remote monitoring options

Choose a flow meter that balances performance with minimal upkeep, especially in hard-to-access areas.

7. Set Your Budget With Long-Term Costs in Mind

While initial cost is important, focus on total cost of ownership. That includes:

- Installation expenses

- Downtime during calibration

- Repair and replacement costs

- Energy consumption

Some meters have no moving parts, which often translates to lower maintenance over the life of the device. Investing more upfront in a higher-quality meter can often save money in the long run.

8. Choose a Reputable Manufacturer

Always go with proven technology from manufacturers with strong support, warranties, and a track record of reliable service.

For an in-depth comparison of various flow meter types and their applications, the U.S. Department of Energy offers a valuable resource.

Real-World Example

Let’s say you’re running a geothermal heating system in an industrial plant. You need to monitor both water and glycol mixtures at varying temperatures. After evaluating your fluid type, pipe diameter, and need for mass flow accuracy, you determine a Coriolis flow meter is ideal. It handles viscous fluids well, doesn’t require long straight runs, and delivers high accuracy.

By applying the principles of how to choose the right flow meter, you avoid a mismatch that could cost thousands in reinstallation and downtime.

Conclusion

Choosing the right flow meter isn’t a one-size-fits-all decision. It requires a thorough understanding of your application, fluid properties, accuracy demands, and environmental factors. Take the time to evaluate each aspect carefully, and always consider the long-term performance, not just the price tag.

As a company dedicated to delivering accurate, reliable, and maintenance-free energy measurement solutions, we know firsthand how critical it is to get this decision right. With the right flow meter in place, you’ll enjoy improved efficiency, fewer headaches, and better data for your operations.

Now that you understand how to choose the right flow meter, you’re better equipped to make a smart, informed investment that supports your business for years to come.

FAQ

1. What is the best flow meter for my application?

The best flow meter depends on your fluid type, flow rate, pipe size, accuracy needs, and environmental conditions. Understanding how to choose the right flow meter involves evaluating these variables to match the right technology to your specific use case.

2. How do I know if I need a mass or volumetric flow meter?

Use a mass flow meter (like Coriolis or thermal) when measuring the actual mass of fluid, especially if temperature or pressure fluctuates. Use a volumetric flow meter (like turbine or electromagnetic) when you’re interested in the volume under standard conditions.

3. Which flow meters require the least maintenance?

Non-mechanical flow meters such as ultrasonic or electromagnetic types typically require less maintenance because they have no moving parts. This makes them ideal for applications where reliability and uptime are critical.

4. Can one flow meter work for all fluids?

No, different fluids (gas, liquid, steam, slurries) require different types of meters. There is no universal solution, which is why learning how to choose the right flow meter for each application is essential.

5. What should I consider when installing a flow meter?

Consider straight pipe runs, flow direction, pipe orientation, and access for maintenance. Some meters, like clamp-on ultrasonic types, offer easier installation with minimal disruption.

6. How accurate are flow meters?

Accuracy ranges widely depending on the type. Custody-transfer-grade meters can be accurate to ±0.1%, while basic mechanical meters may be around ±2–5%. Always review real-world accuracy data, not just lab specs.

7. Do I need to calibrate my flow meter?

Yes. Even low-maintenance flow meters should be periodically calibrated to ensure optimal performance, especially in applications where precision is critical.